Hebei Hankai front wheel oil seal

Special attention should be paid to the seals and bearings, as these elements are critical to the cylinder's operation and longevity Special attention should be paid to the seals and bearings, as these elements are critical to the cylinder's operation and longevity

Special attention should be paid to the seals and bearings, as these elements are critical to the cylinder's operation and longevity Special attention should be paid to the seals and bearings, as these elements are critical to the cylinder's operation and longevity hydraulic cylinder kits repair.

hydraulic cylinder kits repair.

Over time, this could result in irreversible damage to the cylinder and adjacent components, causing delays in production and increasing maintenance costs Over time, this could result in irreversible damage to the cylinder and adjacent components, causing delays in production and increasing maintenance costs

Over time, this could result in irreversible damage to the cylinder and adjacent components, causing delays in production and increasing maintenance costs Over time, this could result in irreversible damage to the cylinder and adjacent components, causing delays in production and increasing maintenance costs 3 inch hydraulic cylinder seal kit. Moreover, a compromised seal could lead to contamination of the hydraulic fluid, which may necessitate a complete system flush and refill – a process that is both time-consuming and expensive.

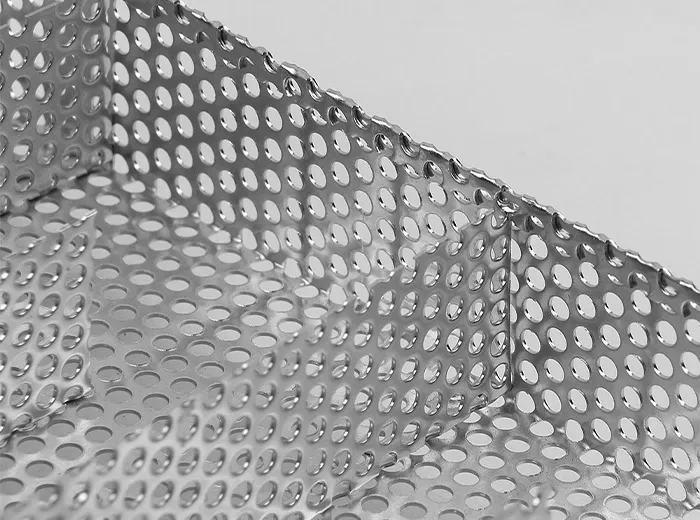

3 inch hydraulic cylinder seal kit. Moreover, a compromised seal could lead to contamination of the hydraulic fluid, which may necessitate a complete system flush and refill – a process that is both time-consuming and expensive.Additionally, a cooling rack can help render excess fat from meats like bacon or chicken. As moisture and fat drip away from the meat during cooking, they fall onto the tray or pan below, preventing the meat from steaming in its own juices. This leads to a crispier texture and more flavorful final product.

cooling rack for meat

Moreover, using a rack helps with cleanup. When drippings or juices from marinated meats or roasted vegetables fall, they can pool around the bottom of the sheet pan. By elevating the pan, the rack allows these liquids to drain away, keeping your food cleaner and making subsequent cleaning much easier. Additionally, it prevents food from steaming rather than roasting, which is crucial for achieving that perfect caramelization and flavor intensity.

rack for sheet pan